From Forest to Fuel: The Sustainable Manufacturing Process of Biomass Pellets

Introduction

The journey of biomass pellets begins deep within sustainably managed forests and agricultural fields. The manufacturing process ensures minimal environmental impact while producing high-quality fuel. Let’s explore how biomass pellets are made.

Step 1: Responsible Raw Material Sourcing

-

Sustainable forestry and agricultural practices ensure that wood and crop residues are harvested without depleting natural ecosystems.

-

Certifications like FSC (Forest Stewardship Council) ensure responsible management.

Step 2: Pre-processing & Drying

-

Raw materials like wood chips, sawdust, or straw are collected and dried to optimal moisture levels (8–12%) to ensure efficient pellet production and combustion.

Step 3: Grinding

-

The dried material is ground into a fine, uniform powder using industrial hammer mills.

Step 4: Pelletizing

-

The powdered biomass is compressed through a pellet mill, where high pressure and temperature bind the material without the need for chemical additives.

Step 5: Cooling & Screening

-

Freshly formed pellets are cooled and screened to remove fines or broken pellets, ensuring consistent size and quality.

Step 6: Packaging & Distribution

-

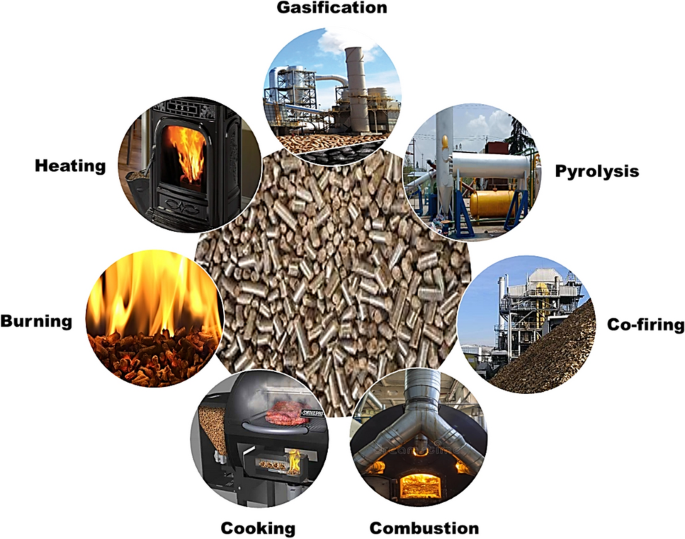

Finished pellets are packaged in bags or stored in bulk silos for easy transportation to domestic, industrial, or power generation customers.

Environmental Commitment

Throughout the entire process, emissions are minimized, and waste is often recycled back into production, ensuring a closed-loop system.

Conclusion

Biomass pellet manufacturing embodies sustainability at every step. By converting natural residues into clean energy, the process supports responsible resource use while providing industries and households with an eco-friendly fuel option.